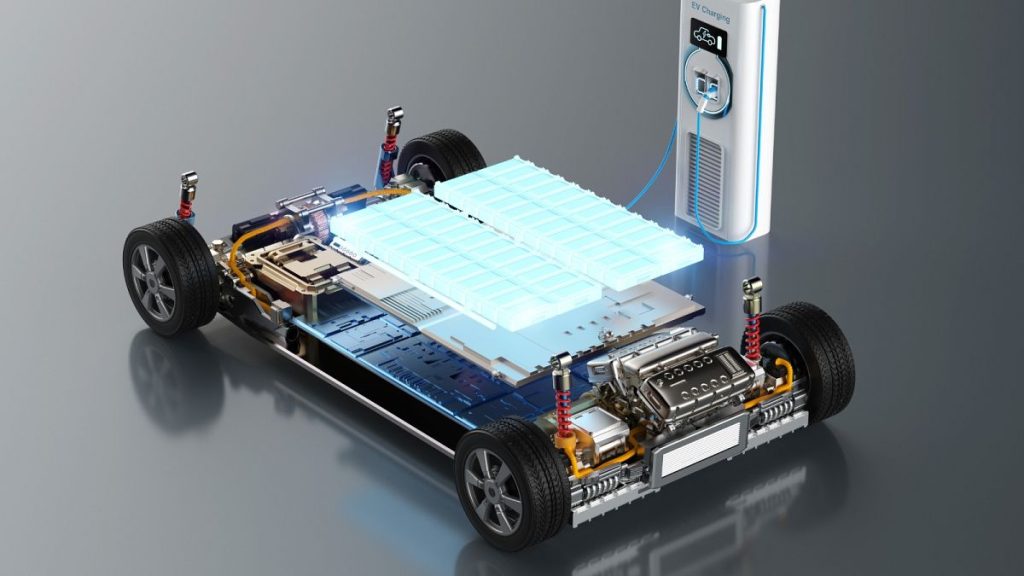

As electric vehicles (EVs) gain traction in the automotive market amid increasing concerns about climate change and the environmental impact of fossil fuels, questions remain about their longevity and end-of-life processes. Electric vehicles are designed with a lifespan comparable to that of traditional internal combustion engine (ICE) vehicles, typically lasting between 15 to 20 years. One of the critical components influencing this lifespan is the battery. EV batteries experience gradual degradation, which affects their ability to hold a charge over time. This raises concerns for consumers looking to purchase new or used battery electric vehicles (BEVs), particularly regarding battery durability and available options once a battery reaches the end of its operational life.

Battery longevity is a major consideration for EV owners, as these batteries are generally deemed to have reached their end of life when they can hold only 70 to 80 percent of their original capacity. However, the advancements in battery technology suggest that many modern EVs can maintain performance beyond this threshold, leading manufacturers to offer warranties extending up to eight years or 160,000 kilometers. Real-world data indicates that, contrary to initial fears about rapid battery degradation, contemporary batteries exhibit extended longevity, often lasting much longer than warranty periods. Consequently, potential buyers should consider these aspects regarding both new and pre-owned electric vehicles.

The costs associated with replacing an EV battery present another vital concern for vehicle ownership. Battery replacement emerges as the most significant expense associated with owning an EV. In earlier EV models, battery issues were more prevalent; however, advancements in technology and management systems have led to a notable reduction in these problems. According to a study by Recurrent in the US, only around 2.5 percent of EVs require battery replacements. Should a full battery replacement be necessary, prices can vary widely across Europe, influenced by factors such as labor costs and market conditions. For example, in Germany, costs can range from €4,500 to €18,600, with notable variances seen among different brands and models, indicating a wider trend across the continent. Price predictions suggest that these costs will decrease as technology and production capabilities improve over time.

When electric vehicles reach the end of their operational life, the concept of a circular economy becomes increasingly relevant. This economic model allows for the repurposing and recycling of vehicle components, notably batteries. Even when batteries are no longer capable of powering vehicles, they often retain significant capacity and can be utilized for less demanding applications, like stationary energy storage. This practice not only extends the life of batteries but also contributes to resource conservation and minimized environmental impact. However, challenges persist in ensuring the safety and reliability of second-life battery applications. The trade-offs involved include delaying the recycling process, which can hinder the reclamation of valuable materials necessary for sustainable recycling practices.

Once batteries can no longer be effectively repurposed, recycling becomes crucial to mitigating material scarcity and reducing the environmental impact of raw material extraction. Lithium-ion batteries, which contain valuable components such as lithium, cobalt, and nickel, can be recycled using advanced techniques like hydrometallurgy and pyrometallurgy. A network of recycling facilities is already operating across Europe, designed to reclaim essential materials while promoting sustainable practices. In addition to batteries, other EV components such as electric motors also contain substantial amounts of copper and rare earth metals, lending themselves to recycling and refurbishment. Nevertheless, the sector faces challenges, particularly the need for standardized processes to ensure efficiency and sustainability across recycling operations.

Looking to the future, battery technology continues to evolve, which could offer benefits for the longevity and performance of electric vehicles. With increasing concern about the scarcity and cost of mining critical materials, many manufacturers are transitioning to lithium iron phosphate (LFP) batteries that are generally more cost-effective, with improved durability and safety. Innovations such as solid-state batteries, featuring a solid electrolyte material, present promising developments that could enhance energy density, longevity, and environmental impacts. However, the mass production of solid-state batteries remains a few years away, emphasizing the need for ongoing advancements in the industry. Understanding the end-of-life processes of batteries is fundamental for promoting sustainability in electric vehicle use.

As the EV market continues to expand, exploring battery longevity, replacement costs, and recycling becomes vital for the automotive industry’s future. The transition toward electric vehicles is not merely about reducing emissions but also involves establishing sustainable practices for dealing with components that have limited lifespans. Continuous improvements in technology, recycling infrastructure, and manufacturers’ adaptability are integral to building a greener, more sustainable future as consumer demand for electric vehicles grows. The industry must navigate the associated challenges while capitalizing on advancements to foster a sustainable approach to electric vehicle ownership and disposal.